Kinder Morgan – Natural Gas Compressor Station Automation

Location: Sidney, Nebraska

Matrix PDM provided engineering services to upgrade three existing compressor unit control systems and the overall Huntsman station control system.

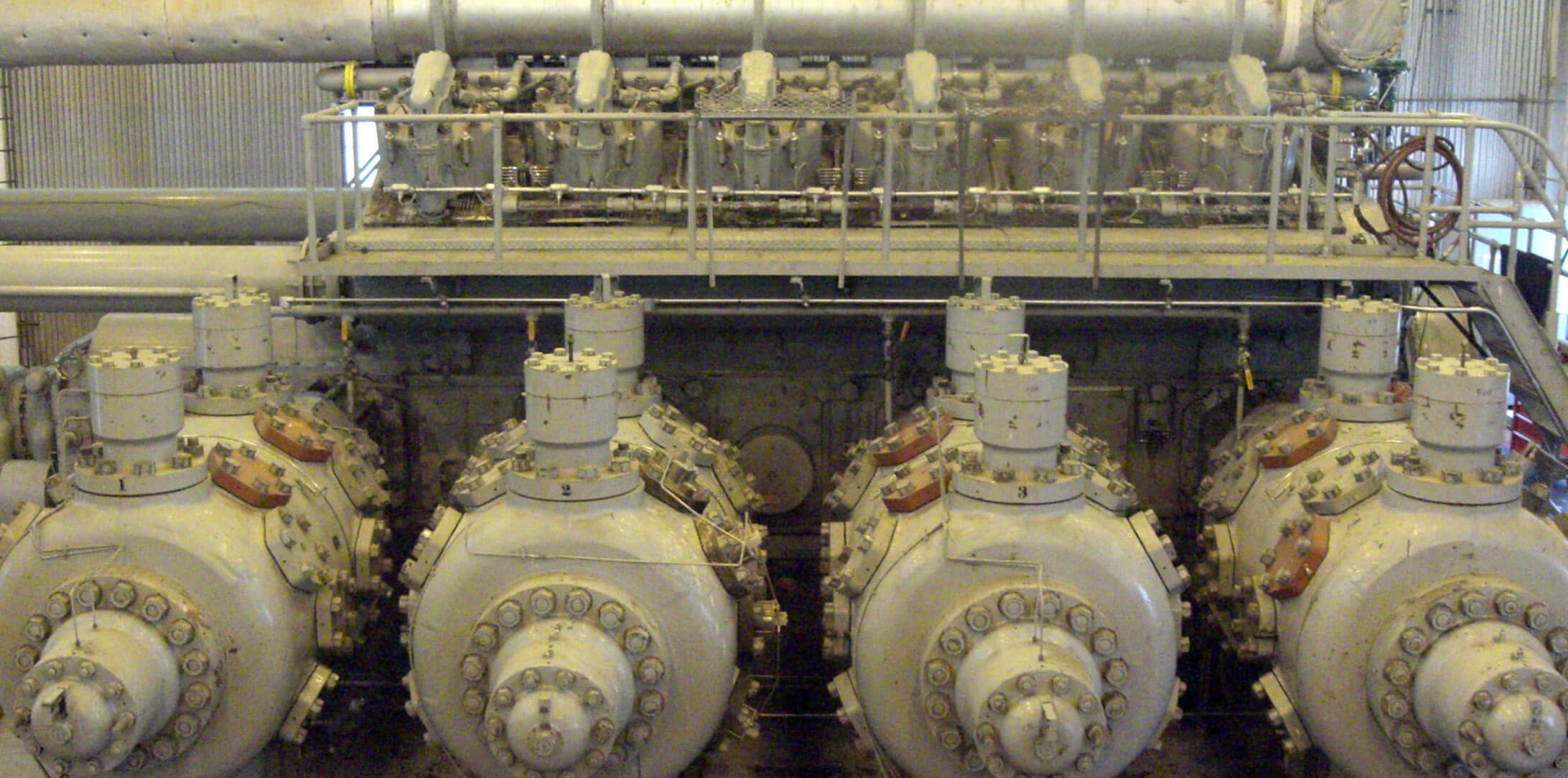

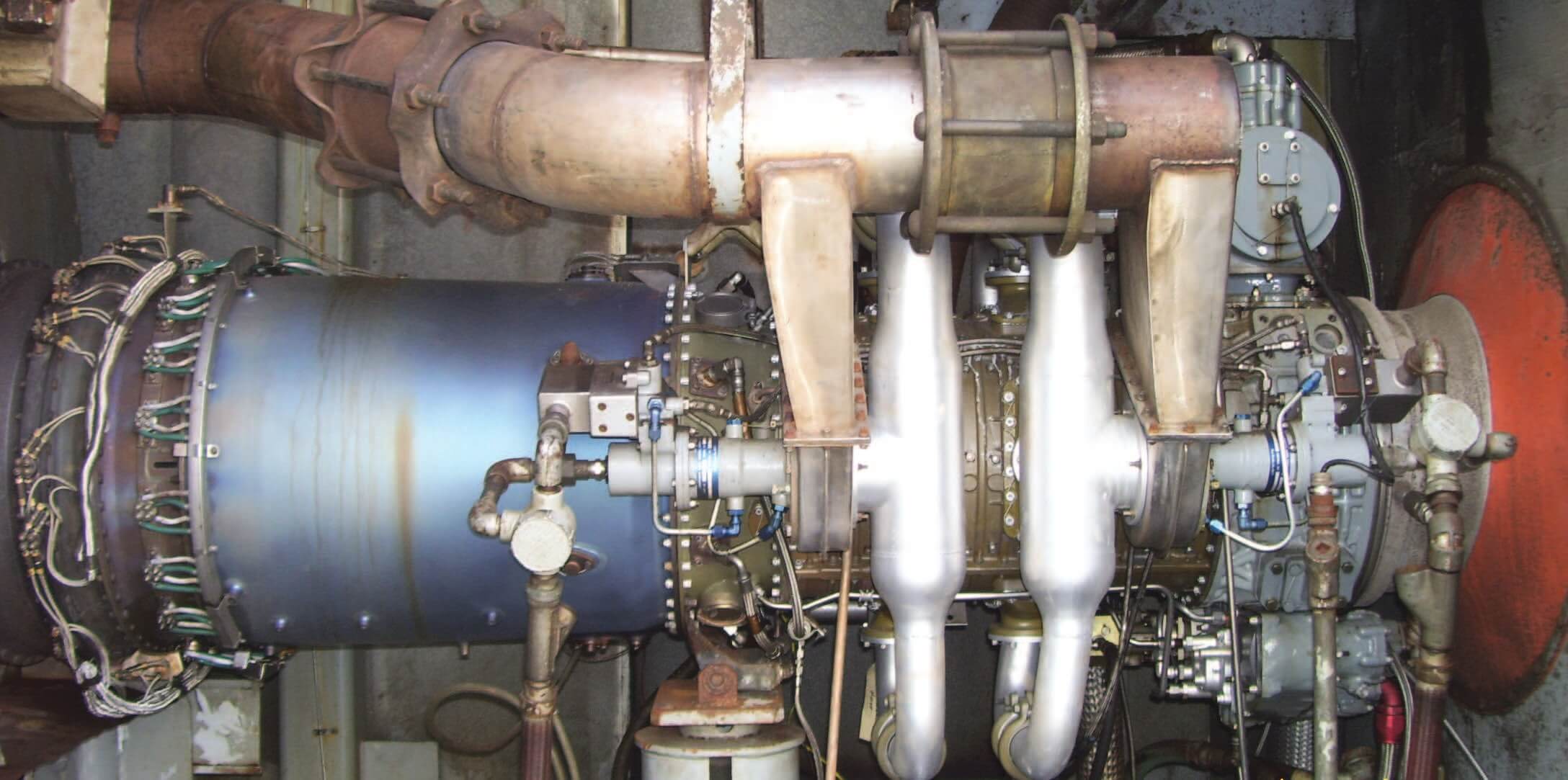

Two compressors were Ingersoll-Rand 1000 HP units and one compressor was a Cooper 1100 HP unit. all of which received new end devices and valve operators.

The natural gas automation team created drawings for the units and station detailing the existing equipment and new equipment. PLC and HMI equipment programs were developed according to Kinder Morgan pipeline standards.

3

compressor upgrades

35+

years of experience

#71

on ENR’s list of Top 400 Contractors

Scope of Work

- Development of a station document that details the operation of the equipment

- Complete simulation of each unit and the station programs in-house prior to commissioning

- Factory acceptance testing in-house with simulation verification from Kinder Morgan

- Development of unit and station commissioning plans

- Allen Bradley processors communicating via ethernet network

- Wonderware, lntouch Human Machine Interface

- Station control logic consisting of remote, local and standby control as well as various flow mode capacities

- Unit control logic consisting of mode control, loading/unloading control and other control algorithms