From Recovery to Reuse

Mark Gilbreath and David Savage, Matrix PDM Engineering, USA, examine the efficiency of sulfurs differing routes to global markets. Read the full article below or download the PDF here.

Owner/operators of refinery or gas processing plants that produce sulfur know it is necessary for molten sulfur to leave the facility at the rate produced. As global supplies of sulfur potentially exceed demand, knowing what happens to the sulfur after it leaves a facility’s gates can help owner/operators make important business and infrastructure decisions in the future.

This article discusses the processes required for sulfur to go from molten sulfur in a rail tank car or tanker truck to being loaded as a granular bulk commodity onto ocean-going vessels in order to meet global demand.

Production of sulfuric acid – sometimes called the universal chemical – is the highest and best use for the sulfur generated by oil refining and

natural gas processing because of its wide use in several processes and

products. Yet frequently, the industries that use or produce sulfuric acid such as the fertilizer industry, are seldom located in the vicinity of the sulfur source. In fact, most sulfur recovery and production can be hundreds or even thousands of miles from a sulfuric acid plant that can consume the volumes produced on a constant basis.

If there is a facility that can send molten sulfur directly by truck to a sulfuric acid plant, it should consider itself very fortunate.

Getting it there

There are several steps molten sulfur must go through before it gets to market. From the refinery or gas plant, it is loaded into rail tanks or trucks for transportation to a sulfur terminal. There, it is unloaded and stored in tanks, then transformed into a granule or prill by a forming unit and stored in either a covered building or outdoor pile. It is then reclaimed from storage before being moved to the hold of a waiting ship by use of a ship loader. This sounds like a straightforward

process, but each step requires several support sub-systems and infrastructure. For this discussion, it will be assumed that a port facility is available that has an existing dock system with mooring for ocean-going vessels and an adequate draft of 12 – 15 m.

Unloading and tank storage

A gravity pit is the most efficient method of unloading molten sulfur from trucks or railcars. This sulfur pit is then connected by piping to specially

designed sulfur storage tanks. The number and size of sulfur storage tanks are determined by the annual throughput of the sulfur terminal. Molten sulfur storage provides a buffer between the overland transportation, the forming unit, and the storage building. This allows the forming unit to operate efficiently without being tied to an irregular flow of materials inbound via rail or truck.

Design and construction of the piping and tank system require specialized knowledge of heating to keep the sulfur molten, but not overheated to the point where molten sulfur becomes too viscous to handle properly. A steam generator and piping, along with condensate return, are required for the controlled operation of this system.

Sulfur forming to bulk product

Two predominant methods are used to transform molten sulfur into solid

particles:

- Granulation, which involves a system of seeding and growing granules in a horizontal fired drum. This creates sulfur that is dry (less than 0.5% moisture) but it can also be quite dusty.

- Wet formed sulfur systems introduced molten sulfur droplets at the top of a counterflow water tank. Droplets change phase to solid and form spherical prills. These prills contain approximately 2% moisture and create less sulfur dust due to the inherent moisture in the particle.

Wet formed sulfur forming systems have been shown to have the lowest requirements for site property, lowest initial capital costs, and lowest utility consumption and labor requirements. Wet formed priller units can be operated with as few as two people. These units can readily be operated in batch modes, started and stopped each day, or only operated on days needed for production. Regardless of the type of system used to form sulfur particles, the material is immediately transferred to conventional conveyor belts for transport through a bulk material handling system to the ship.

Bulk storage and handling

Sulfur particles can now be handled just like any other dry bulk product.

Dust management and particle degradation become new factors. Due to property and geometry considerations, it is seldom possible to convey material from the forming units to ships without multiple transfer points. A small percentage of dust is generated each time the material moves from one conveyor or system to the next.

Spacing between idlers and support systems on conveyor belts should be spaced as closely as affordable to minimize dust generation on long conveyor belt lengths.

Water with high quality surfactant is added to transfer locations as needed to minimise visible dust emissions to meet local air quality standards. The material handling system should be designed in a way to minimise transfers and impact points to minimise generation of new dust. Experience shows the best dust management is to eliminate breakdown and dust generation. By nature, solid sulfur particles are hydrophobic and resist moisture, making dust control by addition of water and surfactant even more challenging.

Material flow characteristics and potential degradation are two important

considerations for the design of the material handling system. When material is transferred from one conveyor belt to another, the geometry and height of the chute work must be designed in a way that minimises impacts to the sulfur prills and directs the material in the direction of the moving belt. Belt widths should be the widest that can be afforded to allow conveyor belt speeds that minimise product degradation that creates dust. The best way to manage sulfur dust is to minimise its creation.

Types of bulk storage systems

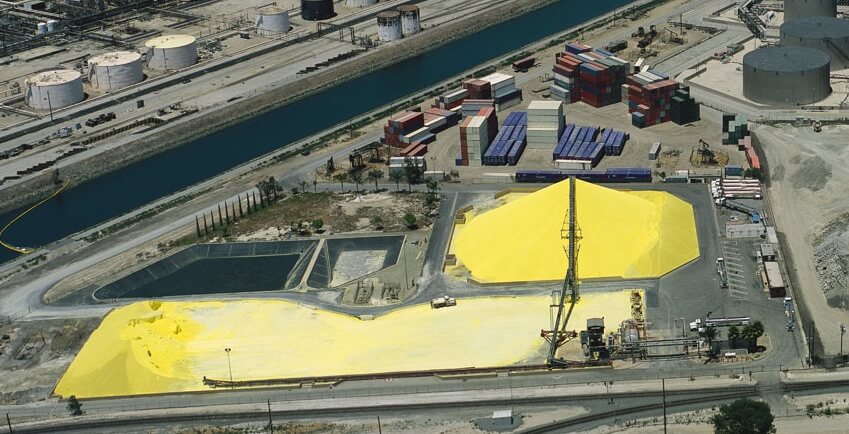

In many locations, it is possible and permitted to store formed sulfur in

open outdoor stockpiles. This makes the stacking and reclaims of the product much simpler. Readily available stacking conveyors are used to distribute the material to stockpile. Mobile equipment such as a front-end loader is then used to reclaim the formed sulfur to hoppers, and then a belt conveyor is used to transport the sulfur to the ship-loader.

Where local permitting or owner preferences require, covered storage comes into play. Covered storage, stacking, and reclaiming is much more complicated and expensive than any open storage system. The foundation system must now not only support the weight of the stacked material, but also the building, conveyors and stacking and reclaiming equipment.

While domes and silos have been utilized for formed sulfur storage, the most practical system is a long A-frame building. As much ventilation should be designed into the building as possible, including open-end walls if allowed by local permit. The length and width of the building are determined by the tonnage of storage needed. Minimum size buildings range from 30 000 t up to 200 000 t. The smaller size would allow the assembly of a small shipload of cargo to be ready for loading upon vessel arrival.

Stacking of material using an overhead traveling tripper conveyor is the

most cost-effective method of placing material in the building. Reclaim can be accomplished by small front-end loaders feeding hoppers to conveyors. This mobile equipment is flexible and less capital intensive but also requires a full-time operator when loading takes place. Often more than one front-end loader is required to meet time limits for ship loading.

Automated track mounted reclaimers have a higher capacity (2000 tph or more) and are the most efficient way to move material from the stockpile to the conveyor belt. This equipment has a higher capital cost than mobile equipment but is more durable and loads at a higher continuous rate.

Combination equipment that both stacks and reclaims is also available. With a single conveyor feed system, this machine can either stack or reclaim but cannot do both at the same time. Separate overhead stacking with a track-mounted reclaimer allows for high throughput capacities. Another major consideration is the ability to have first in/first out stockpile management.

Loading the ship

The biggest opportunity for terminal efficiency is in the ship loader selection. This is also the most capital-intensive part of the terminal. Being able to move the ship loader to allow efficient loading ‘through the vessel’ can minimise time that the ship is at dock and minimise daily demurrage costs.

One ship-loader that travels along the side of vessel feeding from a single high capacity conveyor belt provides the fastest ship loading. With some slewing and shuttling, each area of the ship hold can be loaded effectively. Dust management spray systems are required at all transfer locations, including into the hold during this operation.

Conclusion

Once a facility’s molten sulfur leaves its gates, there are several important

processes and steps along the way – all of which require specialized infrastructure to transform it into global commercial grade for shipping. An understanding and appreciation for these systems can help owner/operators make the right business and infrastructure decisions as they discuss sulfur disposition with their customers, vendors and trading partners who specialize in the sulfur supply chain.