Making the Big Decisions

Bob Watson, Matrix PDM Engineering, USA reviews the foundation options that are available for large scale above-ground facilities and the factors that go in to making the selection. Read more below or download the PDF here.

One of the key decisions to be made in the development of a large scale LNG storage facility field-erected tanks with capacities larger than 200,000 gal. is the type of tank foundation to be utilized. While most of this article’s discussion will be focused on facilities designed and constructed in the U.S., many of the considerations are applicable to other locations worldwide. For the purposes of this article, large scale is considered to be individual

In the US, metallic LNG tanks are designed in accordance with API Standard 625, “Tank Systems for Refrigerated Liquified Gas Storage’; API Standard 620, ‘Design and Construction of Large, Welded, Low-Pressure Storage Tanks for Liquified Gases at -325F or Warmer’. Concrete and foundations are designed in accordance to ACI 376, ‘Code Requirements for Design & Construction of Concrete Structures for Containment of Refrigerated Liquefied Gases’.

Tank containment options

Before a tank foundation approach can be selected, the basic configuration of the tank must be defined, including the method used for spill containment. As discussed in

APl-625 Section 5, the three methods used are single containment, double containment and full containment. Each approach is briefly summarised below.

Single containment

A single containment tank is characterized by an inner tank designed for the cryogenic temperatures of the stored LNG, and an outer tank that serves only to contain vapor and serve as environmental protection for the insulation system. While the outer tank is not designed to contain a leak from the inner tank, secondary containment is designed for this leakage and is usually in the form of an earthen dike.

Double containment

Double containment tanks have an inner tank that is both liquid and vapors tight and an outer tank that is also designed to contain leakage from the inner tank. In this approach, a surrounding earthen dike is not required, as long as there are no penetrations of the inner tank bottom or sidewalls.

Full containment

Full containment tanks have inner and outer tanks that are both liquid tight. The outer tank is also vapored tight. Here, the outer tank is fully capable of containing any leaks from the inner tank and any vapor generated. Again, the earthen dike is not required if there are no penetrations of the inner tank bottom or sidewalls.

As discussed in APl-625, the selection of a containment approach is based upon a risk assessment by the purchaser that considers both onsite and offsite risks. The assessment must also account for any requirements from the authority having jurisdiction at the site. This assessment will identify any fire, blast and missile loads that may require the use of reinforced concrete for the outer tank sidewall and roof construction.

Tank foundation options

The foundation for the LNG tank serves to support the inner and outer tanks and assist with the prevention of detrimental freezing of the soil beneath it. Most large field-erected tanks utilize one of the following foundation types:

- Ring wall

- Slab-on-grade

- Elevated pile cap

Below is a discussion of each of these foundation approaches.

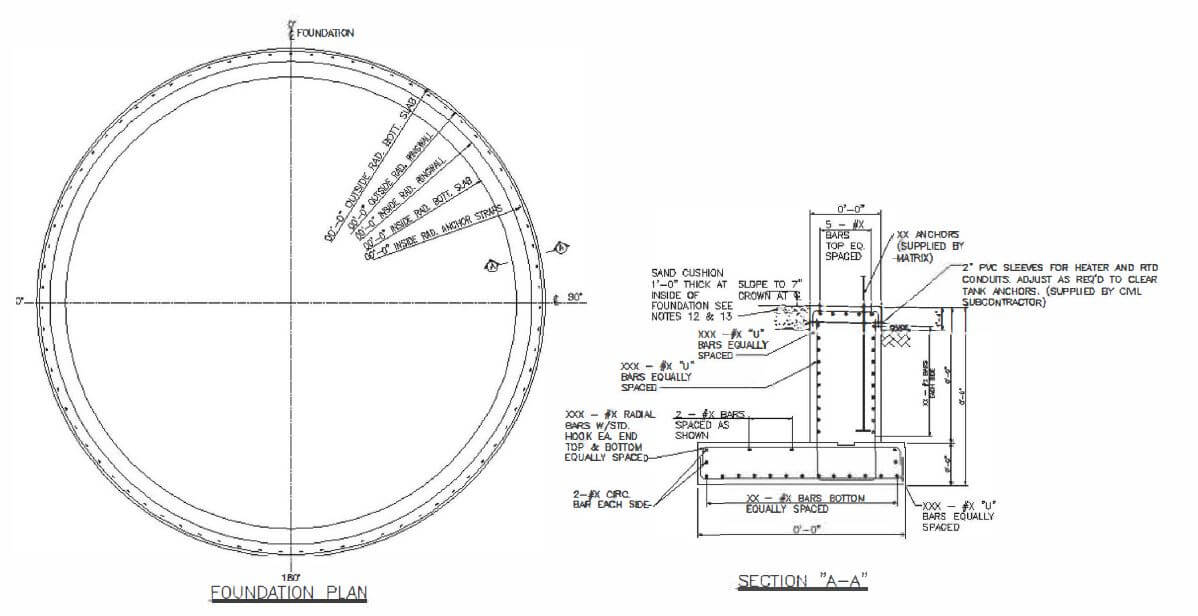

Typical ring wall design:

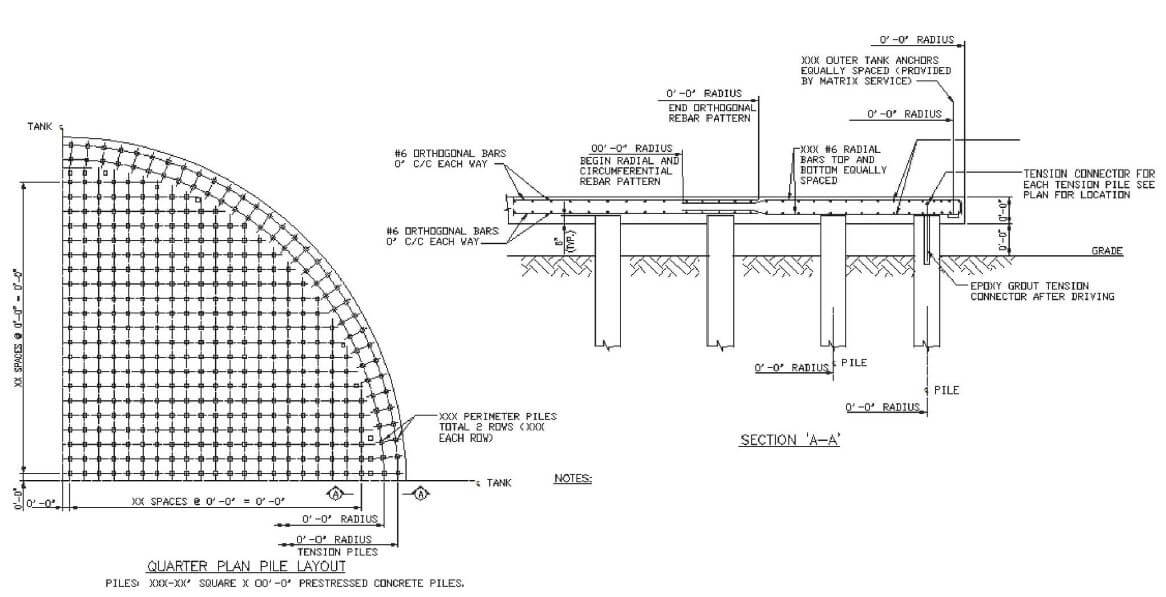

Typical elevated pile cap design:

Ring wall

The simplest foundation type is the ring wall, which has a reinforced concrete ring directly beneath the inner and outer tank walls and the annular insulation space between them. Inboard of this ring, the tank bottom rests directly on a sand layer placed on top of the existing soil. To prevent the soil beneath the ring wall and central sand layer from freezing, heater conduits are embedded into the ring wall and placed in the central sand layer. These electrical heaters can apply varying levels of heat and are controlled by an SCR controller based upon feedback from embedded resistance temperature detectors (RTD). The ring wall approach is used where the existing soil conditions are good and allowable soil bearing pressures are high enough to permit an economical proportion of tank height and tank diameter.

Slab-on-grade

A slab-on-grade foundation has a reinforced concrete slab beneath the entire outer tank bottom. This slab can be constant thickness throughout or may be thicker in the outer region below the inner and outer tank walls and insulation annulus. Freeze protection heater conduits for this approach are embedded in concrete across the entire tank bottom. This foundation approach is used where soil conditions are poor and allowable bearing pressures are low. It can be used with piles, stone columns or other soil improvement methods that support the foundation slab.

Elevated pile cap

When existing soil conditions require the use of piles, another option is to provide an elevated pile cap supported on the piles extending above grade and resulting in an air gap beneath it. When used, this air gap is normally 2 – 3 ft high. With this approach, foundation heating is not required since the air gap eliminates the direct thermal conduction path between the LNG tank and the soil beneath. An additional advantage of this configuration is that the air gap provides a degree of protection from stormwater flooding of the outer tank.

Foundation selection considerations

The selection of a foundation type to be used for the LNG tank is a process that involves both the purchaser and the tank design organization. Below are the areas that need to be investigated for this decision.

Soil conditions

The primary factor to be considered is the condition of the soil at the site. From a comprehensive geotechnical investigation in accordance with ACI-376, the geotechnical consultant can make recommendations on the foundation approach and the allowable soil bearing. This investigation typically involves onsite testing using sample borings and penetrometer testing, followed by laboratory examination and testing of the samples. Soils that are found to be competent can utilize the economical ring wall foundation. Competent soils would be those with increased bearing capacity and minimal predicted tank settlement. More challenging conditions will require the use of piles or a form of soil improvement and a slab-on-grade or elevated pile cap underneath the tank.

Tank containment type

As discussed, the tank containment approach needs to be selected based upon a risk assessment. This decision will limit the foundation types that are feasible with that tank configuration. Single containment tanks can be designed using all three of the foundations. Double and full containment tanks with concrete outer tanks, however, generally require a slab-on-grade or elevated pile cap. This is due to the need to pass forces and moments from the outer concrete wall into the floor slab.

Site seismicity

The geotechnical investigation for the tank site will also address the probability of earthquakes and the design accelerations to be considered by the tank designer.

High seismic conditions generally favor the ring wall or slab-on-grade foundations due to their lower center of gravity. Elevated pile caps tend to amplify earthquake ground accelerations and require more robust tank structures. Soilstructure interaction analysis also becomes more complicated with piles and an elevated cap.

Foundation heating

As noted, foundation heating needs to be considered if the supporting soil will be cooled by the LNG tank, which will result in frost heave. Foundation heating systems have

been used for many years and have been refined from early installations. These systems require periodic maintenance and testing however and do add to the electrical load for

the facility. Care must also be taken to prevent moisture infiltration into the conduits, which can degrade or corrode the heaters and monitoring RTD.

Some owners choose to forego the issues associated with foundation heating and instead opt for an elevated pile cap. While this tends to add to the initial capital cost, it also reduces the cost of ongoing inspection, maintenance and possible heater replacement.

Installation cost

The simplest and most cost-effective foundation type is the ring wall. If soil conditions and containment requirements permit it, this will be the lowest initial cost approach. Due to the additional concrete and reinforcing steel required, and the cost of any soil improvement, the slab-on-grade is more costly to install.

The elevated pile cap has the highest cost due to additional formwork and the cost of pile installation. One option to reduce the formwork cost for the air gap is to place an elevated layer of sand after pile installation and then use it as a form for the bottom of the cap. This sand is then removed using water jets after the slab has cured.

Conclusions

The keys to establishing a cost-efficient large scale LNG storage facility are:

- The early performance of the risk assessment to determine the required spill containment approach.

- The early and comprehensive geotechnical investigation to determine the existing soil conditions.

- A clear understanding of site and permitting constraints that can drive specific styles of spill containment and can, in turn, impact foundation options.

Once these three efforts are complete, the tank design organization can develop a tank and foundation design that minimizes the overall project cost.

If the site lends itself to single containment and has good soil conditions, the foundation can be a ring wall. When soil conditions are poor, or if double or full containment are needed with a concrete outer tank, a slab-on-grade may be required. If the purchaser prefers to avoid foundation heating systems, a pile-supported cap foundation will be needed.