LNG and NGLs

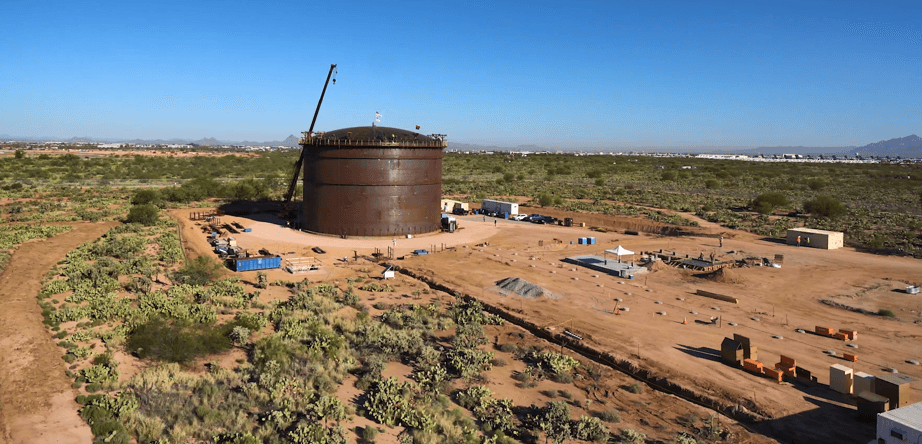

Matrix is a total solutions provider for single and full containment LNG (liquefied natural gas) and NGL (natural gas liquids) storage facilities. With the national demand for natural gas on the rise and the use of NGLs span nearly all sectors of the economy, Matrix has mastered the seamless transition between FEED and EPC, while remaining a single contracting agency with full LNG and NGL project execution capabilities.

LNG is created by transforming natural gas into a liquid state and cooling it to take up less space. Once it has been warmed to become natural gas, it is dispersed through pipelines for use by homes and businesses.

NGLs are composed exclusively of carbon and hydrogen. Ethane, propane, and butane are all NGLs that are used as for cooking and space heating, petrochemical plants, vehicle fuel, and more.

Matrix PDM Engineering offers design excellence with other subsidiaries Matrix NAC (union) and Matrix Service (non-union) offering the highest level of skilled labor in construction and EPC.

Among Matrix PDM’s most prominent engineered products are LNG, low temperature and cryogenic storage facilities, as well as the associated process systems. When choosing Matrix, clients will benefit from not only updated technology, but also a collaborative approach and high repeatability potential to execute subsequent projects.

Matrix PDM is the first EPC company based in the United States to be licensed by GTT (Gaztransport & Technigaz) to offer membrane tank technology. GTT membrane technology builds upon Matrix PDM’s decades of experience in the traditional design and construction methods used for LNG and NGL tanks.

Matrix has successfully delivered an extensive list of diverse industry-leading LNG and NGL projects and are excited to continue expanding into this division of critical work. Our past and current experience with LNG bunkering, peak shaver facilities, and more have positioned us to see projects through to completion safely, on time, on spec, on budget and with the quality you expect.

LNG and NGL services:

- Conceptual design and feasibility studies

• Front End Engineering and Design (FEED)

• Detailed design

• Engineering, procurement, and construction

• Partner with experienced Matrix construction subsidiaries Matrix Service and Matrix NAC.