General engineering capabilities – Specialty Vessels

Specialty tanks and vessels are everywhere. They are used across a wide range of industries serving countless functions. You’ll find them midstream, downstream and in chemical, aerospace, industrial and wastewater applications.

Specialty tanks and vessels are everywhere. They are used across a wide range of industries serving countless functions. You’ll find them midstream, downstream and in chemical, aerospace, industrial and wastewater applications.

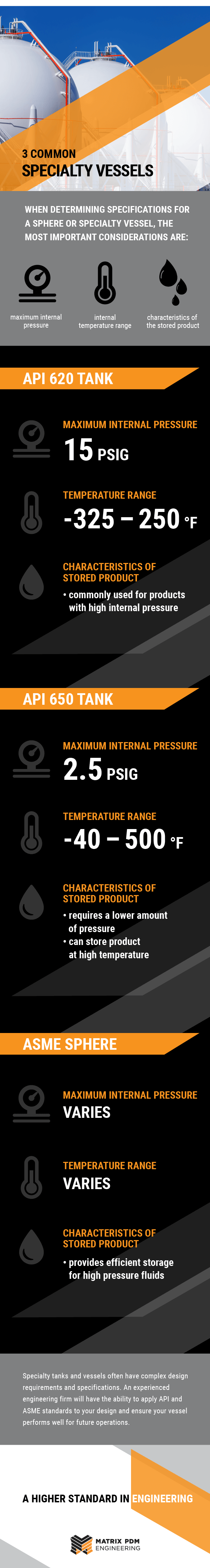

When determining specifications for a sphere or specialty vessel, pressure, internal temperature, and the stored product are the most important considerations.

The American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) set strict standards that dictate how tanks, vessels and spheres should be built. These regulations enhance the safety of industry operations and assure quality. Additionally, these standards serve as a common playbook for everyone involved.

Let’s take a look at three common specialty vessels.

API 620

The API 620 tank is most commonly used for products that have high internal vapor pressure such as liquefied natural gas. It requires an elevated or flat bottom to store it. The tank can store any liquid as long as the internal pressure does not exceed 15 psig. Stored product can range from -325 F to 250 F. An API 620 tank can be built from carbon steel, austenitic, stainless steel and nickel alloys.

API 650

These tanks are some of the most common tanks in refineries, terminals, and other process facilities. The API 650 tank requires a lower amount of pressure compared to the API 620. This tank is limited to 2.5 psig. However, it can store product at a much higher temperature. Stored product can range from -40 F to 500 F. These tanks can be made from carbon steel, austenitic stainless steel, duplex stainless steel or aluminum.

ASME Sphere

Spherical shaped storage is used for gas or liquid applications. Of all of the non-refrigerated 15 psig+ pressurized specialty vessels or tanks, the ASME sphere requires the least amount of ground space. This advantage also creates additional benefits. The foundation required to support the sphere can be smaller and therefore more economical. The shape of the sphere has less external surface area, offering lower costs for coatings, accessories and piping than many other options. Internally, the sphere offers efficient pressurized storage due to uniform stress distribution.

Specialty tanks and vessels often have complex design requirements and specifications. An experienced engineering firm will have the ability to apply API and ASME standards to your design and ensure your vessel performs well for future operations.