An Overview of Natural Gas Processes

At Matrix PDM Engineering, we understand you have a choice when it comes to choosing among the best companies for natural gas processing. When you partner with us, you choose a world-class team of engineers with a wide range of expertise. With natural gas processing, we seek to serve our clients’ diverse needs through these diverse areas of expertise:

At Matrix PDM Engineering, we understand you have a choice when it comes to choosing among the best companies for natural gas processing. When you partner with us, you choose a world-class team of engineers with a wide range of expertise. With natural gas processing, we seek to serve our clients’ diverse needs through these diverse areas of expertise:

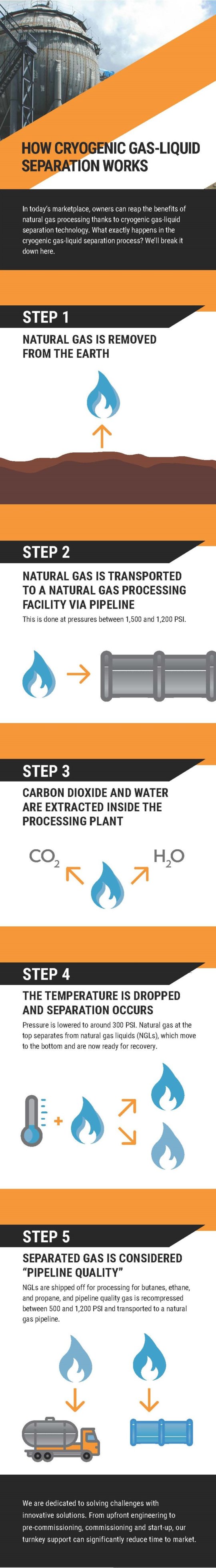

Cryogenic liquids recovery

The successful recovery of cryogenic liquids requires a processing plant capable of safely and efficiently separating out natural gas liquids like butane, propane and ethane. Our experience runs deep with a deep knowledge of both gas recovery and plant design.

Amine treating

To make gas fit for transportation and utilization, hydrogen sulfide and carbon dioxide must be removed from gases through amine gas treating. This form of treating is a core service we offer, and an essential capability customers demand when it comes to natural gas processing today.

Fractionation

With separation processes, fractionation is vital since it breaks down NGLs (natural gas liquids) into usable base components. Our step-by-step process is bolstered by our unrelenting focus on safety, budget and timing. And that’s the reason customers return to us for not only fractionation, but other natural gas processing services, too.

Liquid NGL stabilization

Optimizing liquids means optimizing for storage and transportation, too. That’s why NGL stabilization is a key service we provide to clients to meet storage, transportation and deadline goals.

Sulfur recovery, processing and handling

When it comes to sulfur recovery, processing and handling, our proprietary technology converts molten sulfur into solid granules. Whether it’s sulfur forming, facility design, sulfur blocking, sulfur melting or operations expertise, we can help.

Gas compression

With gas compression, we provide full-service multidiscipline design and complete automation — and we have the flexibility to deliver with even the most challenging circumstances.

Natural gas dehydration

With the removal of water from natural gas, we believe our separation services are beyond comparison. It is a necessary step to remove water in natural gas through dehydration, and when you partner with us, you will see our combination of expertise and technology is second to none.

Pipeline station development and design

The list is nearly endless when it comes to optimizing efforts for pipeline station development and design. With safety, scheduling and budgets at the forefront of everything we do, we are ready to help you with your next pipeline station development and design undertaking.