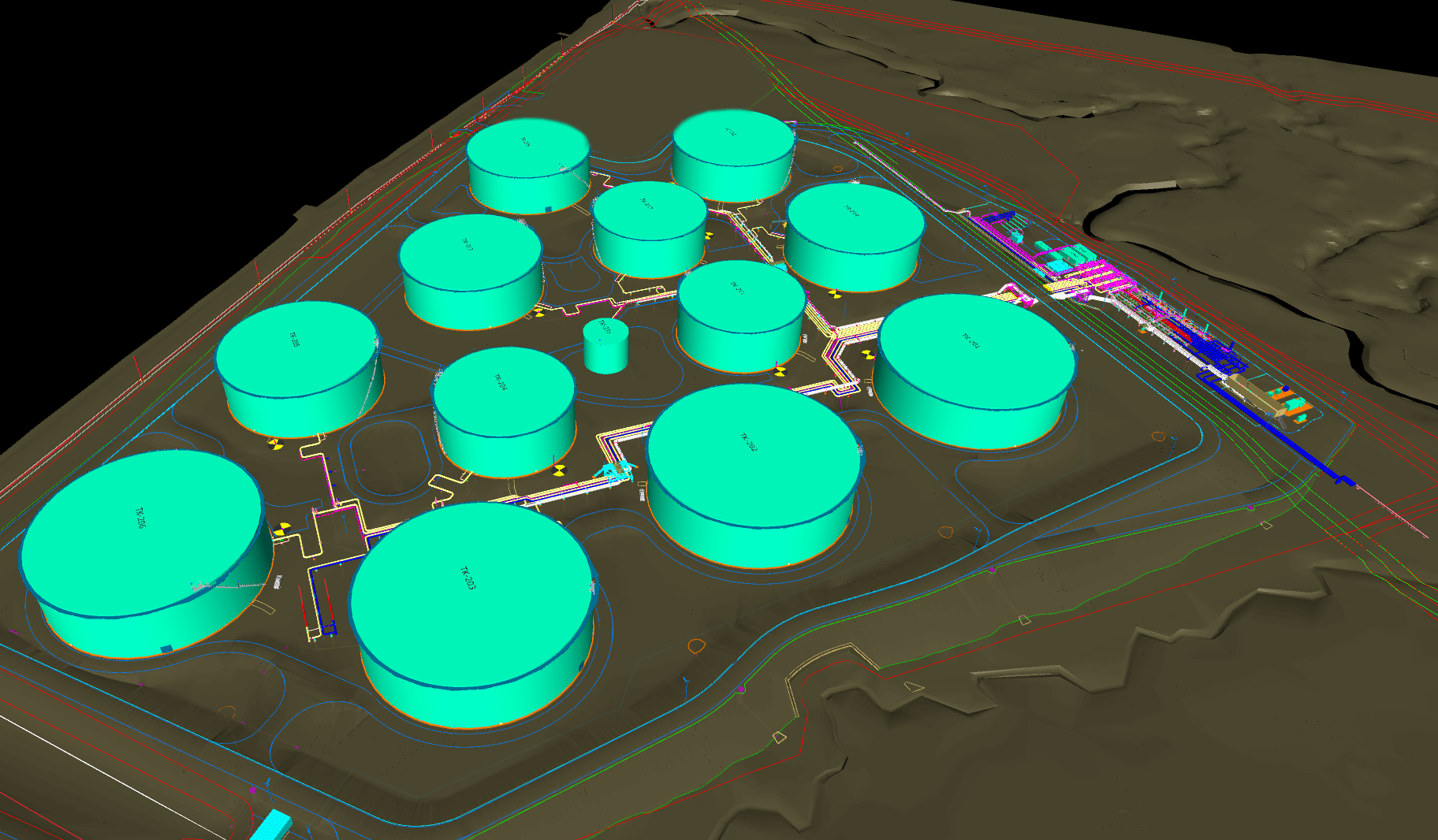

Norfolk Southern Corporation – Ethanol Rail Transfer Facility – Material Handling Systems

Matrix PDM Engineering provided mechanical and electrical engineering services to develop the scope and final design for the bulk transfer facility in Chattanooga, TN.

The project included detailed design of a complete piping header system that allowed the connection of all 12 ethanol cars being unloaded simultaneously at 700 gallons per minute. This included structural, mechanical and power distribution design for the facility. Detailed

bill of materials was provided to allow for complete contractor bids to be selected by the client.

The facility unloads 12 railcars through a single piping header. The system provides for two truck loading stations in addition to the capability to pump to an adjacent tank storage facility.

Scope of Work

- Mechanical and electrical design services

- Two truck loading stations

- Ethanol metering system

- Vapor containment and recirculation

- Detailed mechanical and electrical design

- Quantities for bids by contractors